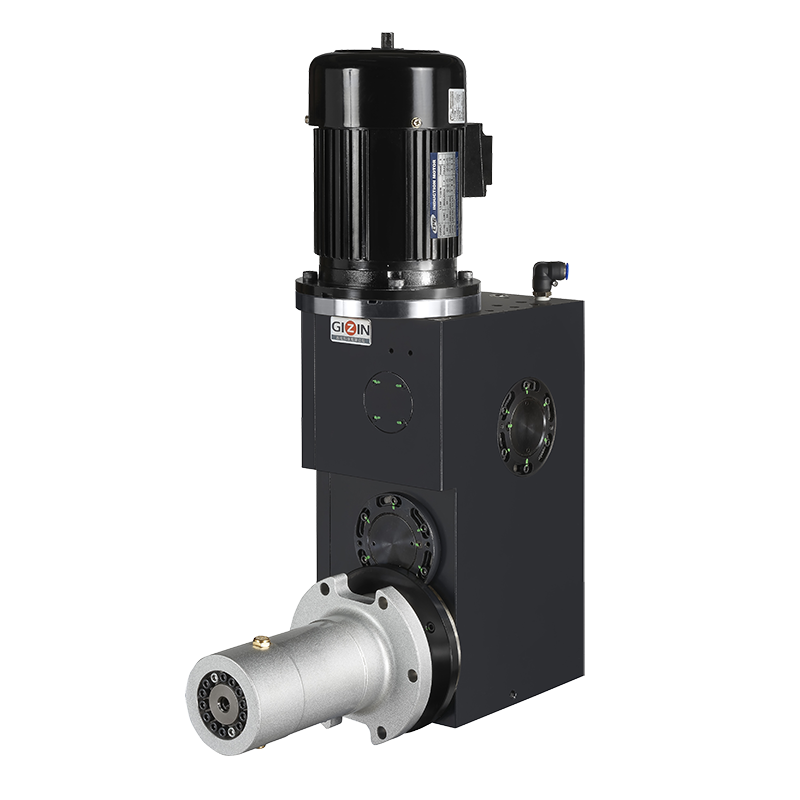

GE-40 A65 CNC Cambox

#40 Horizontal Automatic Tool Changer

Using CAM technology to achieve the fastest and most stable mechanism tool change action, automatic printing machine, automatic medicine packing system ,automatic food process line, IC industries manufacture system, Automobile assembly line, automatic parts exchange system, etc., All using the CAM component as the main parts.

Features:

*Sold over 900 sets to Japanese market

*Ball type Cam, High strength

*Totally enclosed

*Cycle time 0.9 sec.

*MAX. tool weight 12kg

Product Inquiry

Features:

*Sold over 900 sets to Japanese market

*Ball type Cam, High strength

*Totally enclosed

*Cycle time 0.9 sec.

*MAX. tool weight 12kg

Specifications

TYPE

A65

USE ON

#40 TAPER MACHINES (HORIZONTAL)

ARM TRAVEL

115mm

ARM LENGTH(RADIUS)

250 ~ 300mm

MAX TOOL WEIGHT

4 ~ 8kgx2

CYCLE TIME

1.2 ~ 2 Sec

SWIVEL ANGLE

60° ~ 90°

DRIVE MOTOR

0.75KW

SENSOR

ENCODER / SERVO

LUBRICATION

OIL BATH

NET WEIGHT

100kg

FAQ

How often does the lubrication oil need to be replaced?

Check oil lever every month. If it is lower than normal lever, it needs to fill up. Regularly check the oil quality every month. If the oil color is darkening or the oil is emulsion. Please replaced immediately.(Check from oil gauge)

Change the oil every 2400 hours of machine working time.

What are the features and advantages of GIZIN cambox?

- The most complete automatic tool changer product for selection.

- The fastest tool changer.

- With the longest product life cycle.

- Provide lightweight products.

- Modular design, which can be combined and matched according to customer needs.

- Customized product.

What products and services can GIZIN provide?

- Vertical tool change system

- Horizontal tool change system

- Customized tool change system

- APC

- Lightweight aluminum tool changer arm