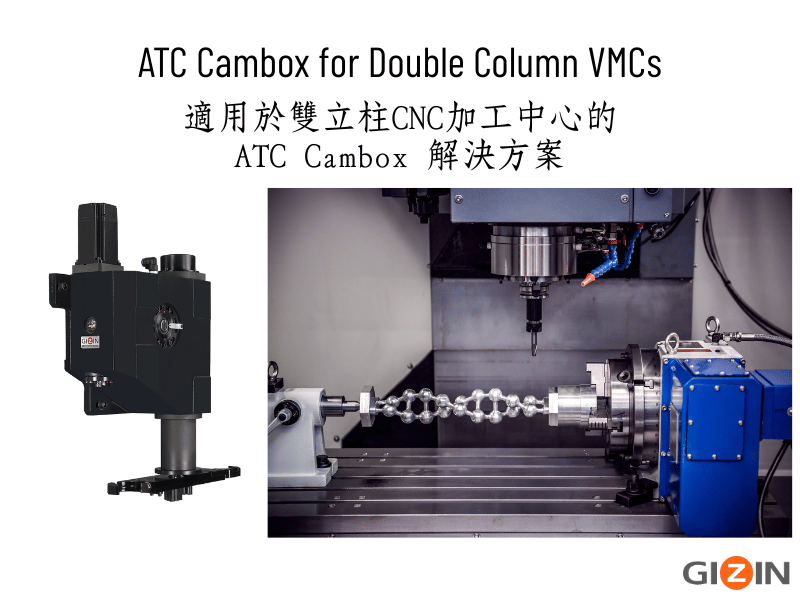

ATC Cambox for Double Column VMCs

Introduction

In industries where precision, scale, and productivity define success — such as aerospace, automotive, and energy — the Double Column Vertical Machining Center (VMC) has become an indispensable asset. Known for its rigidity, large machining envelope, and stability under heavy cuts, the double column VMC is the go-to choice for processing oversized parts, molds, and structural components. However, the full potential of these machines can only be realized with the support of highly efficient Automatic Tool Changing systems, particularly the ATC Cambox, which ensures reliability and speed during complex machining operations.

________________________________________

Aerospace: High Precision on Large Structures

In the aerospace industry, components such as wing spars, fuselage frames, engine mounts, and landing gear housings demand not only ultra-precise tolerances but also the ability to handle large, awkward workpieces. Double column VMCs offer:

- • Superior rigidity to maintain tight tolerances over long machining cycles

- • Large working areas that accommodate oversized aluminum and titanium parts

- • Stability against thermal deformation during continuous high-speed cutting

However, machining aerospace-grade alloys often involves multiple tool changes — sometimes over 50 per part — including drills, mills, reamers, and specialty cutters. This is where our ATC Cambox comes into play. It enables:

- • Fast, reliable tool changes to maintain spindle uptime

- • Smooth, vibration-free operation to ensure surface integrity

- • Reduced thermal and mechanical stress on the spindle during tool engagement

With a precise ATC Cambox, manufacturers can meet the stringent aerospace requirements for quality and productivity, without compromising on machine longevity.

________________________________________

Automotive: Speed and Flexibility for Mass Production

In the automotive sector, where component uniformity and fast cycle times are essential, double column VMCs are increasingly used for:

- • Engine blocks and transmission housings

- • Chassis and suspension parts

- • Aluminum and steel dies for stamping and forming

These machining processes require rapid tool changes between roughing and finishing tools, often within seconds. Our Automatic Tool Changer Cambox plays a critical role by offering:

- • High-speed tool changes that minimize idle time

- • Consistent repeatability to maintain dimensional control across large production volumes

- • Compact, durable design to support long hours of uninterrupted production

By integrating our ATC Cambox into double column machines on the automotive line, manufacturers can reduce changeover delays and meet just-in-time production targets with confidence.

________________________________________

Energy Industry: Handling the Demands of Large-Scale Components

The energy sector — particularly wind, oil & gas, and nuclear — involves machining of very large and heavy parts like:

- • Turbine housings

- • Generator casings

- • Heat exchanger plates

- • Structural brackets and flanges

Double column VMCs are ideal for this domain due to their large table sizes, robust cutting capability, and high-load spindle heads. Yet, the complexity of these parts means:

- • Frequent tool changes with heavy-duty tools

- • Tool switching under high chip load and pressure

- • Need for consistent precision on multi-surface machining

Our ATC Cambox addresses these needs by enabling safe and accurate tool changes, even under extreme conditions. Its self-locking pin mechanism and stable cam design help prevent tool drop, reduce wear on the spindle, and ensure longer service life — all crucial when machining mission-critical energy components.

________________________________________

Why the Right ATC Cambox Matters

A Double Column VMC is only as efficient as its tool change system. Without a fast, stable, and reliable ATC Cambox, even the most powerful machine will suffer from avoidable downtime, accuracy loss, and tool wear.

Our ATC Cambox is engineered to complement high-end double column machining operations with:

- • Self-locking mechanism to prevent tool drop during extraction

- • Reduced impact on the spindle, preserving machining accuracy and spindle life

- • Compatibility with vertical and horizontal CAM-type machines

- • Low-noise, high-efficiency operation for demanding production environments

- • Retrofittable design, allowing upgrade of existing machines without interrupting production

________________________________________

Conclusion

Double column VMCs are foundational machines in the aerospace, automotive, and energy sectors — capable of machining large parts with exceptional precision. But to truly unlock their performance, manufacturers must pair them with intelligent automation, especially in tool handling.

That's where our Automatic Tool Changer Cambox delivers the advantage — providing the speed, precision, and reliability needed for uninterrupted, high-performance production.

Contact us today to learn more about how our ATC Cambox can be integrated into your double column CNC machines to elevate your manufacturing capabilities.