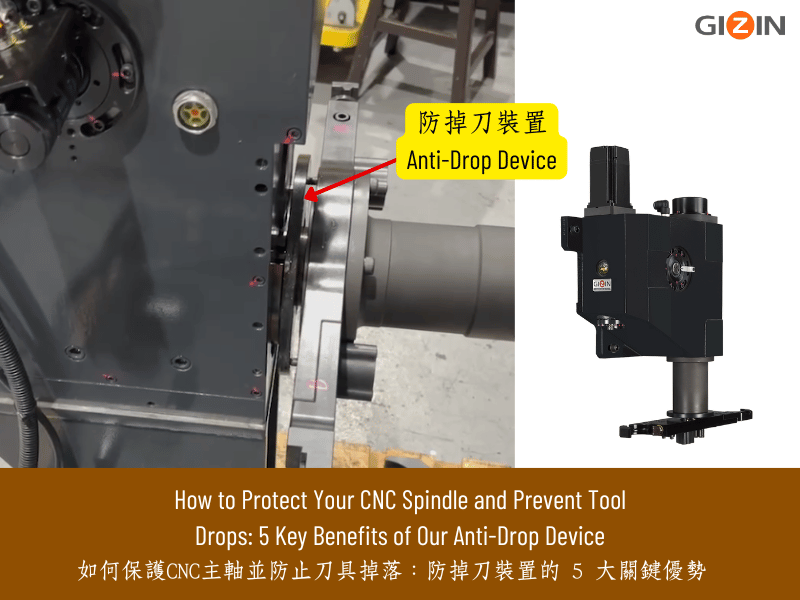

How to Protect Your CNC Spindle and Prevent Tool Drops: 5 Key Benefits of Our Anti-Drop Device

Introduction

In CNC machining, automatic tool changers (ATCs) streamline production by enabling rapid and seamless tool changes. However, the process of tool changing comes with its own set of challenges. One critical issue that many manufacturers face is the risk of tools dropping during the changeover. This can lead to damaged tools, compromised machine components, production downtime, and potential safety hazards for operators. To address these issues, we’ve developed an Anti-Drop Device that ensures tool changes are performed safely and efficiently.

Common Issues During Tool Changes

1. Tool Drop Accidents:

When tools are not securely held during the changeover process, they may accidentally fall. This can damage the tool, machine components, or even pose a risk to operator safety.

2. Spindle Impact:

During a tool change, if the tool arm doesn’t handle the tool securely, it can cause unwanted impact on the spindle, affecting its longevity and machining precision.

3. Noise and Inefficiency:

Older or improperly maintained tool changers can create excessive noise and reduce the efficiency of production lines.

4. Limited Compatibility:

Many existing solutions lack flexibility, making it difficult to implement safety features across different types of CNC machines, such as vertical and horizontal machining centers.

Our Anti-Drop Device: A Comprehensive Solution

To tackle these issues, our Anti-Drop Device offers a reliable, adaptable, and efficient solution. Here’s how it works and why it stands out:

1. Self-Locking Mechanism for the Tool Arm:

Our system allows the tool arm’s locating pin to engage a self-locking function before extracting the tool. This ensures the tool is securely held in place, preventing accidental drops during the changeover process. This feature enhances operator safety and protects expensive tools and machine components.

2. Minimizing Spindle Impact:

By securely locking the tool before extraction, the system reduces unnecessary impact between the tool arm and the spindle. This minimizes wear and tear on the spindle, extending its service life and maintaining machining accuracy.

3. Compatibility with Vertical and Horizontal Machines:

Our Anti-Drop Device is designed to work seamlessly with both vertical and horizontal cam-type tool changers. This flexibility means manufacturers don’t have to worry about machine type when implementing the system.

4. Low Noise, High Efficiency:

The system operates with minimal noise, ensuring a quieter working environment. Its high-efficiency design speeds up the tool change process, improving overall productivity on the production line.

5. Retrofit for Existing Machines:

One of the standout advantages of our system is that it can be added to existing machines. There is no need for costly equipment overhauls. This retrofit capability ensures that even older machines can benefit from the enhanced safety and efficiency our system provides.

Key Advantages at a Glance

- Prevents Tool Drops: The self-locking function ensures tools are secure before extraction.

- Protects the Spindle: Reduces impact, extending spindle life and maintaining precision.

- Versatile Compatibility: Works with both vertical and horizontal cam-type tool changers.

- Quiet and Efficient: Low noise operation enhances efficiency on the production line.

- Easy Retrofit: Can be installed on existing machines without disrupting production.

Conclusion

Tool drops during the automatic tool change process are a serious concern that can lead to costly damages and safety risks. Our Anti-Drop Device offers a reliable, efficient, and adaptable solution that addresses these challenges head-on. By enhancing safety, extending spindle life, and improving production efficiency, this system is an essential upgrade for any CNC operation.

Call to Action

If you are interested in implementing our Anti-Drop Device or want to learn more about how it can improve your machining processes, please contact us. Our team is ready to assist you in ensuring safer and more efficient production.